Preparing for the Winter

Every year, before the first freeze, Winterization becomes the most important consideration for all irrigation systems in regions located where the frost level extends below the depth of installed piping.

- Freezing water in the backflow assembly will damage the internal parts and can crack the brass body. This can be a very costly repair.

- Even if you have drained the water out of your irrigation system, some water left over and can freeze, expand, and crack the Polyethylene pipe.

To minimize the risk of freeze damage, you’ll need to winterize your irrigation system properly. It is best to use the blowout method as this helps ensure all the unwanted water in the system has been removed.

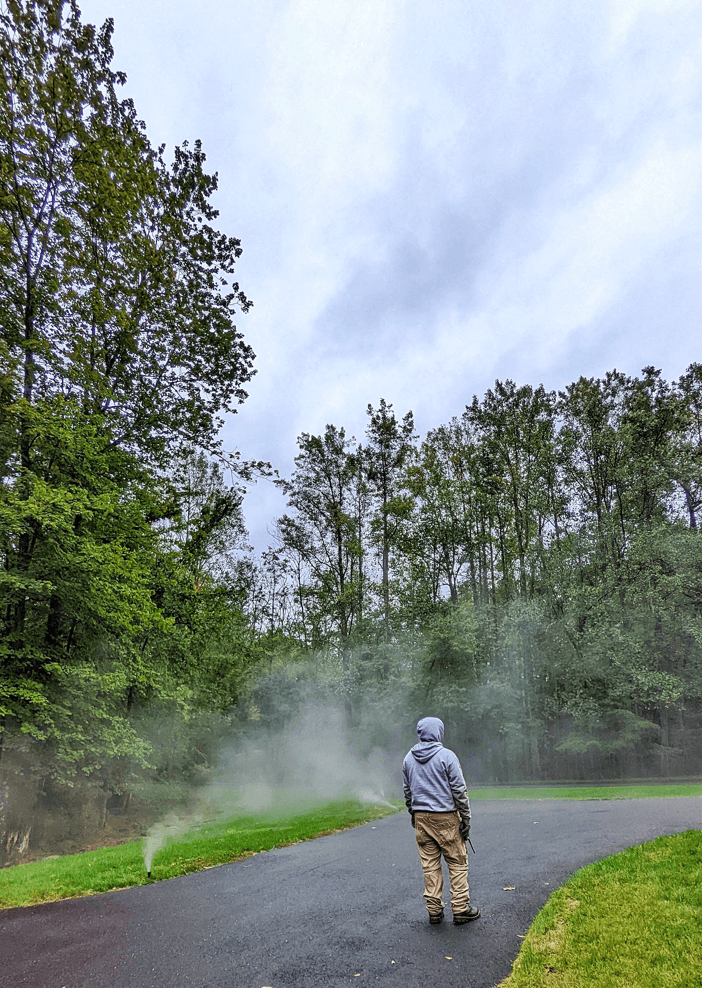

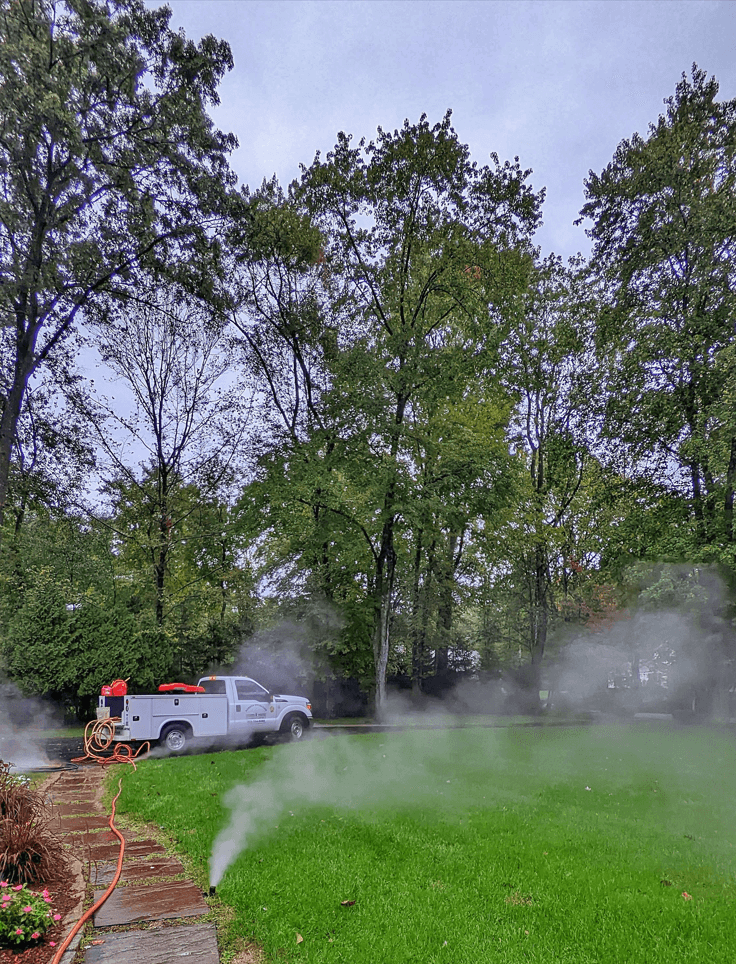

The blow out method uses pressurized air to push the water out of the irrigation system. The air compressor specifications should be 80-100 cubic feet per minute (CFM) for any mainline of 2″ or less. The blow out pressure should remain below the maximum operating pressure specification of the lowest pressure rated component on any zone in the system and should NEVER exceed 80 PSI.

Note: Small shop compressors will not have enough CFM to properly winterize the system.

Once the compressor is properly connected to the irrigation system with the main water line shut off, each zone is activated starting from the furthest zone from the compressor, slowly working your way to the closest. Each zone is left open until no water can be seen exiting the heads; this normally takes approximately two minutes or more per zone. It is better to use two or three short cycles per zone than to have one long cycle during the winterization process.

Once the water has been removed from the irrigation system, disconnect the air compressor and release any air pressure that may be present. If your backflow device (the most common backflow installed is called a Pressure Vacuum Breaker) has ball valves, open and close the isolation valves on the backflow device numerous times to ensure that any trapped water has escaped from the upper areas. Leave the isolation valves open at a 45° angle (approximately 1/2 open) and open the test cocks.

Note: Once a given zone is dry, you should stop blowing through that zone as this could cause damage to the system.

There is another method called it “Manual Method” that is used when manual valves are located at the end and low points of the irrigation piping. To drain these systems, simply shut off the irrigation water supply and open all the manual drain valves.

Once the water has drained out of the mainline, open the boiler drain valve or the drain cap on the stop and waste valve (whichever is used in your area) and drain all the remaining water that is between the irrigation water shut off valve and the backflow device. Open the test cocks on the backflow device. If your sprinklers have check valves, you’ll need to pull up the sprinklers to allow the water to drain out of the bottom of the sprinkler body. Depending on the location of the drain valves, there could be some water left in the backflow, the piping, and the sprinklers. When all the water has drained out, close all the manual drain valves.

If you’re in the Connecticut area, don’t hesitate to contact Dobson to find a solution that works for you. We are here to serve them with the best and most qualified team. If you find yourself out of our service area, contact your local reputable irrigation provider.